Toolbox Topic: Prevent hand injuries with PPE and awareness

We use our hands for virtually every task we do at work, and because of this fact, they are commonly injured on the job. By keeping our hands and fingers out of harm’s way and wearing the correct PPE, we can prevent hand injuries. Plan all activities to eliminate hand hazards by understanding the hazard and the hand placement and protection of hands.

Three common types of hand injuries

The three most common types of hand injuries in the workplace are lacerations, crush injuries, and fractures.

- Lacerations: Lacerations are the most common type of hand injury. Lacerations, or cuts, are caused by sharp objects or tools. Lacerations can be prevented by using a glove rated for the task.

- Crush injuries: Crush injuries are usually caused by an individual placing their hands in the line of fire between two objects or in a rotating piece of equipment. Pinch points on equipment or tools can also commonly lead to crush injuries.

- Fractures: Factures can occur when there is a sudden blow to the bones in the fingers or hands.

Wearing the correct personal protective equipment (PPE) can help prevent hand injuries. PPE that is too large or too small may not properly protect the wearer from hazards and could create additional hazards. If you’re unsure what PPE is right for the job, be sure to stop work and ask your safety officer.

If PPE is the selected method of hazard control, recognize that hand protection is based on the hazard. Safe work practices include:

- Use the right kind and type of glove for the job. Understand the limitations of your gloves and what they are appropriate for.

- Make sure hand placement is safe. Think through the entire process of using the tool.

- Avoid hand contact with material that has sharp edges.

- Be proactive. Think about hazards before beginning the job.

- Use tools to remove your hands from the line of fire, such as using push sticks to operate a table saw.

- Never put your hand into an area where you cannot see it.

- Never work on an energized piece of equipment. Lock and tag out equipment to ensure there will be no unintentional stat-up while working on the equipment.

- Pay attention to where your hands are around any moving parts or any objects that have the potential to move.

- When working with others, be sure to communicate to let each other know if you are out of the line of fire before moving objects or starting equipment.

Prepare for potential hazards

Before beginning any task, look for potential hazards. Hazards that can cause hand injuries include:

- Missing guards on equipment

- Pinch points

- Sharp edges

- Hot work

- Chemicals

- Vibrations

- Electric shock

- Tools with sharp edges or abrasive surfaces

- Equipment that has potential to injure hands, such as an angle grinder, power saw, etc.

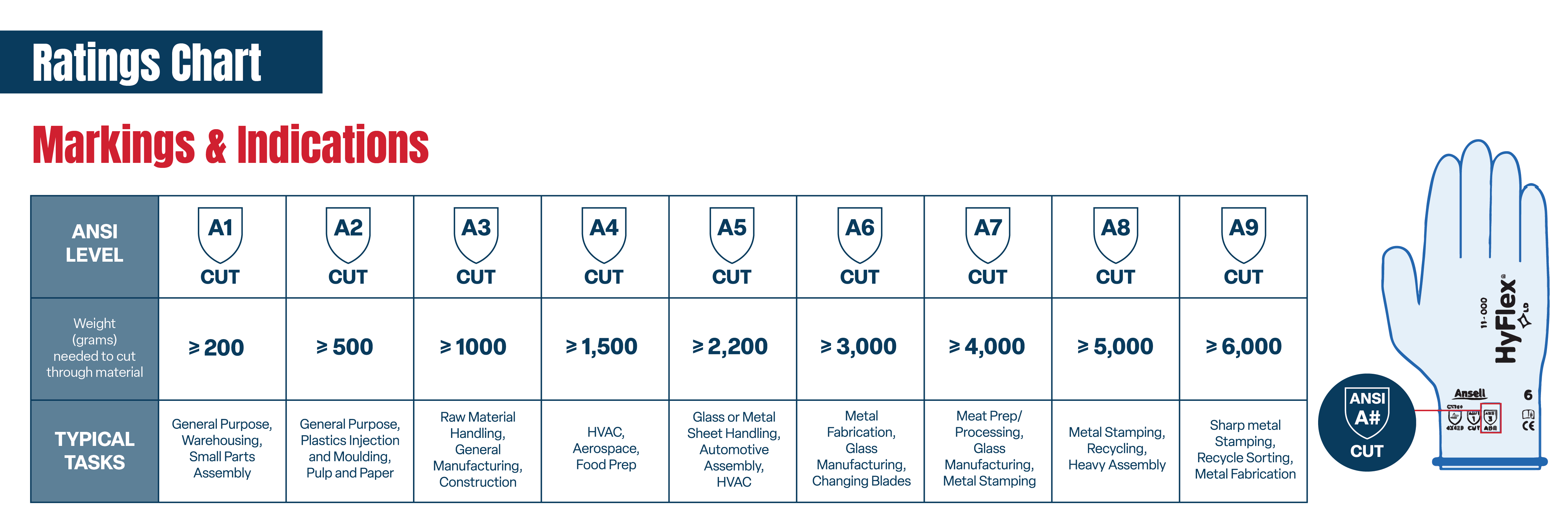

Understand Glove ANSI Levels

One way to prevent hand injuries is to wear the right job for the task. Understanding the ANSI levels for gloves will allow you to choose the right glove.

Providing the right PPE on the jobsite is critical. AMECO can help standardize PPE on jobsites, which enhances safety and increases efficiency. Learn more about PPE programs in our Tools and Supplies Site Services.

MORE

BACK TO NEWS & INSIGHTS